Text Ulrich Kläsener ––– Photography

How can you ensure reliable, automated data exchange between CAD applications and ERP, PDM and PLM systems?

If you compare the three-man start-up from the 1980s with today’s SME with a global reputation, you quickly realise that it’s not its size that has made Teledoor Melle Isoliertechnik GmbH the great company it is. Rather, the success of this classic manufacturer of variants has been due to its determination to supply every customer with the correct solution to the highest standards and never to say “no” to a customer – a mindset that continues to this day. Teledoor Melle Isoliertechnik GmbH, which is based in Lower Saxony, has been producing chiller and freezer cells and chiller and freezer chamber doors – products that have been tried and tested many times over – for more than 30 years. However, when a business refuses to lower its standards in any way whatsoever in terms of its focus on customers – just as Teledoor has always done – it can encounter problems when it comes to traditional engineering-to-order. These problems can relate to margins, competitive ability or even issues within the team, since complex tasks also mean extra work. This increases exponentially as more and more orders come in, which is why Teledoor started looking for opportunities to boost efficiency – especially in view of the in-house realisation that the design department, with its 27 CAD workstations, was becoming more and more of a bottleneck and was no longer managing to use the full capacity of production.

FOCUSING ON PAIN POINTS

When potential was analysed, three weak points were identified – the CAD department, the processes and the strategy. First of all, the design department was failing to keep pace with incoming orders because too much repetitive work was proving both hugely time-consuming and prone to errors. As Daniel Krämer, Head of IT & Digitalisation at Teledoor, explains: “Only a tiny fraction of the work actually involved the task at hand, i.e. design.” There was also a mismatch between the amount of work involved and the return it produced in the spare parts business, because this always had to be approved by the design department so that the standard interfaces to the ERP could be accessed. “What’s more, we needed to do something, because we were expanding our database unnecessarily,” Krämer continues. “Many components were identical and yet had multiple article numbers due to being copied in the PDM system. Finally, an overview and a clear line were lacking, because certain standards were getting lost in a design department of more than 20 people.” Interdepartmental communication, for example when changes are made to an order at short notice, was the acid test. “Such changes can lead to complete chaos if data redundancy occurs, too – from creating the order in text form and implementation in a CAD design to information for production, for example,” Krämer adds.

A NEW ERA IN ENGINEERING

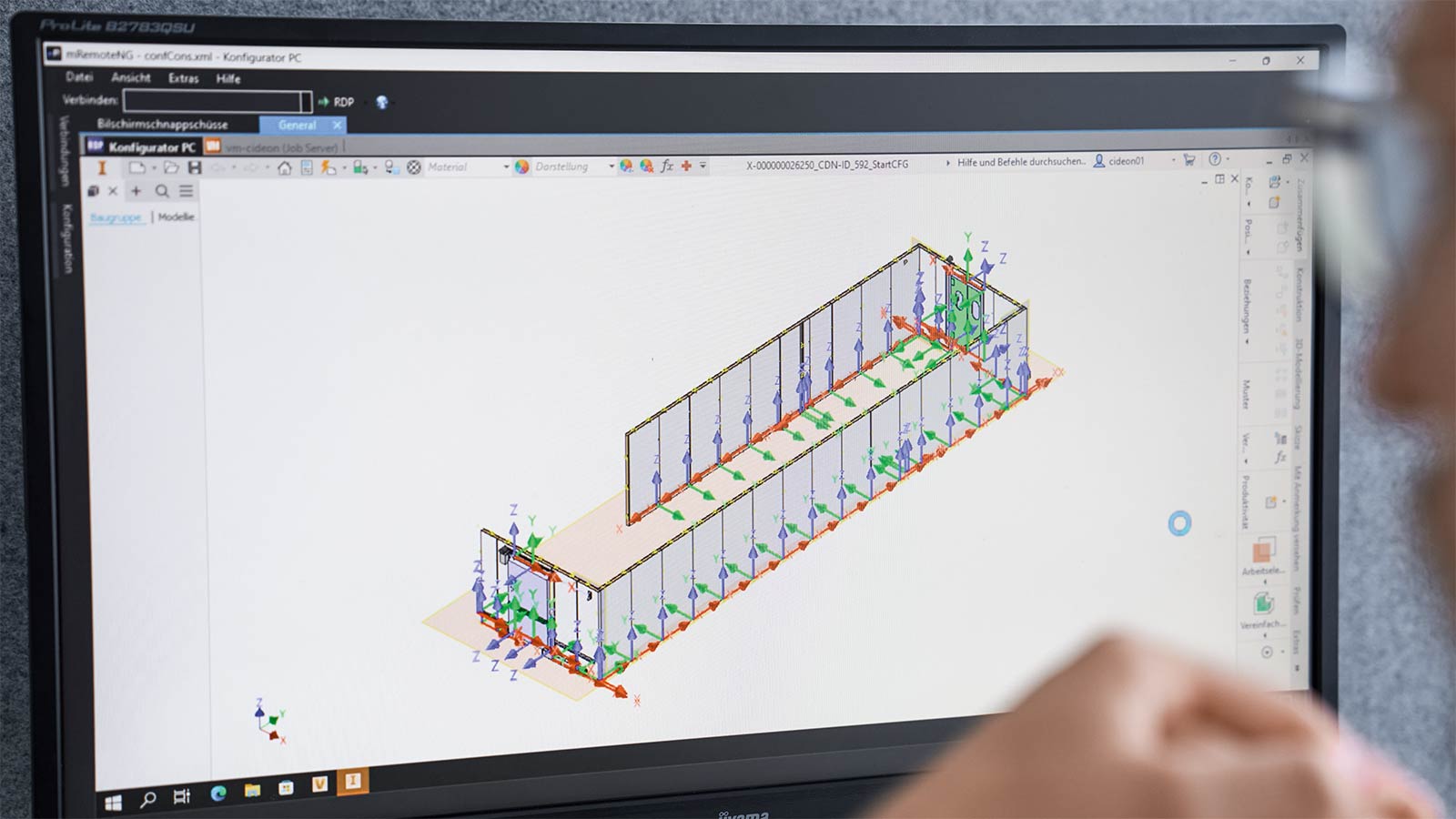

So what is the answer? “It quickly became clear that we needed to opt for a disruptive approach if we wanted to make real progress,” says Krämer. This led Teledoor to scrutinise entire process chains more than individual work steps. When looking into variant design in the PDM/ERP segment, Krämer came across Cideon, one of the few system integrators with combined CAD, PDM and ERP expertise. “We were particularly attracted by the Cideon assertion that the engineering-to-order principle does not preclude automation,” explains Krämer. After initial talks, Cideon and Teledoor got down to work straight away. It took them less than eight months to achieve what they had set out to accomplish – a no-touch process from customer enquiry to production, whereby the fully automated design process does not require a single stroke of manual work, at least in the case of configurable standard products. The configure-to-order solution that Cideon and Teledoor got up and running in record time is based on Cideon Conify. This customisable and configurable software solution combines the Teledoor sales and engineering data and integrates the various systems involved, such as ERP, CAD and PDM. In terms of the process, the product is configured by the sales team using the user interface that has been set up. It is then generated automatically in the form of a CAD data set and saved in a PDM-compliant format. This all takes place in no-touch mode, because documentation, parts lists and work plans are generated automatically and passed on to the order processing and production departments.

Facts & figures

70 %

is the percentage of orders that Teledoor ultimately wants to cover with its “no-touch process”, with the remaining 30% being handled by the design department.

15 min

is the length of time between the product parameters being entered by the sales staff and the start of production.

8 months

is the amount of time it took to launch the configure-to-order process – which is more than three months faster than Teledoor was expecting.

DIFFERENT – AND SIGNIFICANTLY BETTER

Although the route taken to achieve configure-to-order was not easy, it was coherent. Teledoor divided the project into three work steps – first, entering the mother elements into CAD, followed by the actual CAD automation via iLogic and, finally, handing over the production documents. With help from Cideon, Teledoor designed the intuitive configurator cockpit for the in-house sales team. After just eight months, the new process “spat out” the first tangible product. This was a pleasant surprise for Krämer. “We had initially scheduled around a year to achieve a productive working environment with full automation,” he explains. “In practice, a member of the sales team goes to a front end in the ERP, enters the relevant product parameters in the user interface and presses a button. In theory, the order can be launched on the downstream machine 15 minutes later, without any further human intervention. In the past, this sometimes took up to two weeks, partly due to delays in the process,” he continues. What’s more, extra work due to changes to an order is now a thing of the past. “And, of course, the design work for 50 percent of our standard products – that’s the current figure – was cut from 100 percent to zero percent. One direct effect is that, by eliminating the time spent on design work, we are now competitive in the freezer cell segment once again. We offer top-quality, precisely dimensioned cells at outstanding prices – whereas some other suppliers only offer off-the-shelf cells that are available in their catalogues.” As he also explains, Teledoor is ultimately aiming to cover 60 to 70 percent of all orders via the no-touch process, with 30 to 40 percent being handled by the design department. He is keen to emphasise that manual design work is definitely here to stay, even if this is to be reduced to a minimum by means of a hybrid design method called “no touch plus”. The aim here is for the Teledoor design engineers to use the configurator to achieve a 70 percent approximation, before designing the remaining 30 percent – which usually involves much more complicated execution – themselves. In any event, nobody will be aware of the new design method at Teledoor. Krämer explains: “The process is so seamlessly integrated that no questions will be raised.” In terms of business economics, use of the Cideon Conify solution at Teledoor is already producing outstanding results. “The project was, without a doubt, implemented exactly as we envisaged. The ROI can be achieved within one year – I can see that really clearly on the live dashboard,” says Krämer. He then continues: “We didn’t even use up our entire budget, which is really unusual for projects such as this.”